- Home

- Equipments

- Tensile Strength Tester

- Hydraulic GSM Cutter

- Denier Count Wrap Reel

- Yarn Twist Tester

- Yarn Tension Meter

- Yarn Shore Hardnes Tester

- Tearing Strength Tester

- Button Pull Strength Test

- Bursting Strength Tester

- Sample Lab Dyeing Machin

- Color Matching Equipments

- Color Fastness Tester

- Abrasion cum Pilling Test

- Digital Thickness Gauge

- Crease Recovery Tester

- Stiffness Tester

- Repellent Penetration

- Knowledge

- Testing Instruments Guide

- Support

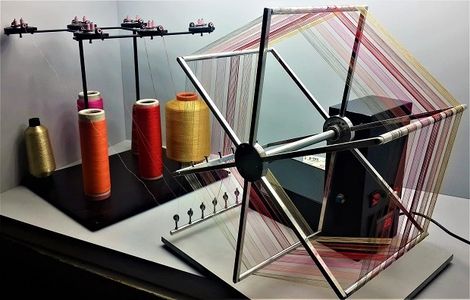

Denier Count Wrap Reel, Denier Count Checking Machine, Denier Wrap Reel, Count Wrap Reel, Digital Wrap Reel, Automatic Wrap Reel, Motorized Wrap Reel

Denier Wrap Reel

Denier Wrap Reel, a 3 lea Automatic Wrap Reel, is used to check Denier / Count of Yarn or to prepare lea. This Yarn Testing Instrument is used to accurately determine count and strength of the various yarns and fibers. Denier Wrap Reel manufactured at B-Tex Engineering is of finest quality and covered by warranty for manufacturing defects.Denier Wrap Reel is a precision made, robust and reliable reading machine which is used for rapid preparation of accurate lengths of yarn, in hank form, for subsequent weighing and determination of count and strength of the yarn. It gives accurate and perfect result of final count/denier of the yarn sample/specimen.

Features of Denier Wrap Reel:

- The equipment consists of solidly constructed swift/wheel.

- It has traverse mechanism.

- Wrap reel is fitted with a digital counter.

- It is powered by a special geared motor.

Specifications of Denier Wrap Reel : Swift Perimeter: 1 Meter (optional) or 1.5 yards

Number of leas made at a time: 3

Spread of each lea: 20 mm

Overall Dimensions of the main Unit: 450mm (L), 260mm (W), 360mm (H).

Net Weight of the main Unit: 3.000 Kg

Overall Dimensions of the cone Unit: 280mm x 260mm x 500mm

Net Weight of the cone Unit: 1.800 Kgs (approx.).

Controls: MAIN, ZERO/RESET CONTROLLER.

How Denier Wrap Reel Works?

- Bobbins/Yarn Cones are placed on the Yarn Cone Stand.

- The end of the yarn has to be passed through the Tensioning Device into the ceramic eyelids, through to the ceramic pigtail and finally onto the plate with screw heads. The free end of the yarn has to be tied on the screw head by making few rounds.

- The mains is put on and the counter is set at desired setting (90 for Denier) with the help of thumb wheel setting.

- After the required revolutions, Wrap Reel will stop automatically.

- The free end of each of the Leas has to be united with the other end of the same Leas. The Bobbin side near the knot has to be cut.

- The collapsible mechanism is lowered in the swift/wheel.

- The made-out leas can be used for determination of count or strength of the yarn etc.

Denier Wrap Reel is confirmed with the standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Count Wrap Reel

Count Wrap Reel is a Automatic Wrap Reel used to prepare 6 lea for checking the denier and count of yarn, etc.

Count Wrap Reel is used to prepare 6 lea for rapid preparation of accurate lengths of yarn, in hank form, for subsequent weighing and determination of count and strength of the yarn.Count Wrap Reel manufactured at B-Tex Engineering is finest quality yet affordable.Count Wrap Reel is a precision made, robust and reliable reading machine which is used for rapid preparation of accurate lengths of yarn, in hank form, for subsequent weighing and determination of count and strength of the yarn. It gives accurate and perfect result of final count/denier of the yarn sample/specimen.

Features of Count Wrap Reel:

- The equipment consists of solidly constructed swift/wheel.

- It has traverse mechanism.

- Wrap reel is fitted with a digital counter.

- It is powered by a special geared motor.

- It is automatic.

Specifications of Count Wrap Reel :

Swift Perimeter: 1.5 yards

Number of leas made at a time: 6

Spread of each lea: 20 mm

Overall Dimensions of the main Unit: 450mm (L), 260mm (W), 360mm (H).

Net Weight of the main Unit: 20.000 Kg.

Overall Dimensions of the cone Unit: 280mm x 260mm x 500mm

Net Weight of the cone Unit: 10.000 Kgs (approx.).

Controls: MAIN, ZERO/RESET.

How Count Wrap Reel Works?

- Bobbins/Yarn Cones are placed on the Yarn Cone Stand.

- The end of the yarn has to be passed through the Tensioning Device into the ceramic eyelids, through to the ceramic pigtail and finally onto the plate with screw heads. The free end of the yarn has to be tied on the screw head by making few rounds.

- The main is put on and start the wrap reel, mechanical counter shows rotations, switch off to stop reel after desired numbers of rotation.

- The free end of each of the Leas has to be united with the other end of the same Leas. The Bobbin side near the knot has to be cut.

- The collapsible mechanism is lowered in the swift/wheel.

- The made-out leas can be used for determination of count or strength of the yarn etc.

Count Wrap Reel is confirmed with the standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Digital Wrap Reel

Digital Wrap Reel, a 12 lea Automatic Wrap Reel, is used to check Denier / Count of Yarn or to prepare lea.

Known as Denier Count Wrap Reel, Denier Count Checking Machine, Denier or Count Testing Instrument.

This Yarn Testing Instrument is used to accurately determine count and strength of the various yarns and fibers. Digital Wrap Reel manufactured at B-Tex Engineering is of finest quality and covered by warranty for manufacturing defects.Digital Wrap Reel is a precision made, robust and reliable reading machine which is used for rapid preparation of accurate lengths of yarn, in hank form, for subsequent weighing and determination of count and strength of the yarn. It gives accurate and perfect result of final count / denier of the yarn sample / specimen.

Features of Digital Wrap Reel, Denier Count Wrap Reel, Denier Count Checking Machine, Denier or Count Testing Instrument:

The equipment consists of solidly constructed swift/wheel.

It has traverse mechanism.

Wrap reel is fitted with a digital counter.

It is powered by a special geared motor.

Specifications of Digital Wrap Reel, Denier Count Wrap Reel, Denier Count Checking Machine, Denier or Count Testing Instrument :

Swift Perimeter: 1 Meter Number of leas made at a time: 12

Spread of each lea: 20 mm

Overall Dimensions of the main Unit: 450mm (L), 260mm (W), 360mm (H).

Net Weight of the main Unit: 20.000 Kg

Overall Dimensions of the cone Unit: 280mm x 260mm x 500mm

Net Weight of the cone Unit: 5.000 Kgs (approx.).

Controls: MAIN, ZERO/RESET CONTROLLER.

How Digital Wrap Reel, Denier Count Wrap Reel, Denier Count Checking Machine, Denier or Count Testing Instrument Works?

Bobbins/Yarn Cones are placed on the Yarn Cone Stand.

The end of the yarn has to be passed through the Tensioning Device into the ceramic eyelids, through to the ceramic pigtail and finally onto the plate with screw heads. The free end of the yarn has to be tied on the screw head by making few rounds.

The mains is put on and the counter is set at desired setting (90 for Denier) with the help of thumb wheel setting.

After the required revolutions, Wrap Reel will stop automatically.

The free end of each of the Leas has to be united with the other end of the same Leas. The Bobbin side near the knot has to be cut.

The collapsible mechanism is lowered in the swift/wheel.

The made-out leas can be used for determination of count or strength of the yarn etc.

Digital Wrap Reel is confirmed with the standards and comes under warranty. All this help provide customer satisfaction that promotes long term customer relationship which is our ultimate objective at B-Tex Engineering.

Minimum 10 years part availability assurance from the date of Invoice.

Technical specifications & appearance of machines are subject to change without any notice

Denier Count Wrap Reel, Denier Count Checking Machine, Denier Wrap Reel, Count Wrap Reel, Digital Wrap Reel, Automatic Wrap Reel, Motorized Wrap Reel